|

|

|

|

The Ultra Tec Owners' Newsletter

Fall 1987

"The Some Times"

|

|

|

Dear Friend,

Dear Ultra Tec Owner,

The Ultra Tec family is like a real family - even to the 'regularity' of

our letters. Usually such a letter starts out with 'I've been meaning to

write but...' -

and that's how this letter starts - we expected to send a letter last

February, BUT we got so busy that there was just no time. Now, that's a

nice kind of problem for us.

For you it's nice too, even if it meant a delay in getting your newsletter.

It's a sign of rising interest in faceting, interest from new people. That's

important - the vigour of faceting depends on new people becoming involved.

I think people are tiring of their computers and VCR's, and feel a need to

be doing something creative. Whatever the reason, it's a welcome development.

Usually, this section of the Newsletter deals with 'news'. Because of the

time that has gone by, however, it's more like 'olds'. But, there are a

few things in my memory that stand out, and it is never too late to offer

congratulations.

|

|

|

First of all, congratulations to Dave Regli for winning the Masters

Trophy at the Facetors Fair last January. This competition has become

the hot one at this show, involving a large field of master facetors.

Dave is an Ultra Tec facetor, which gave him an unfair - or Fair- advantage,

depending how one looks at it, (of the four competitions so far, Ultra

Tec facetors have won three - not quite as good as I'd like). This is

a Single Stone competition, with little room for error. Dave and his

wife have every right to be all

|

|

smiles about his win. Dave will likely be back for another try in 1988,

and perhaps he'll be the first person to repeat a win in this competition.

The Ultra Tec trophy for Best Case was not awarded, there being no score

high enough. That was a disappointment for us, but we've had this situation

once before. Next year, we feel sure there will be someone who adds the extra

effort and concentration, and wins.

Our congratulations are due these two smiling gentlemen - on the left

'Badger Bud' Rogers and on the right John Stacy, both Ultra

Tec facetors. Between them they recently had won six faceting trophies.

|

|

|

Badger Bud had done very well indeed at the Federation Show in Sacramento,

where he won the Johansen Trophy (3 synthetic stones), the Facetron Trophy

(single natural stone) and the Golden Bear Trophy (12 synthetics). John

Stacy won the Southern California

Faceting Guild Best Case Award and the Facetron Trophy (best natural stones)

at the September Fair in Anaheim, and at the San Jose Fair, the Golden City

Trophy (single piece of jewellery). You could just about bet that Bud Rogers

and John Stacy will have their names in the lists of future award winners.

|

|

Just a few words on the Tucson Show - as usual it was an exciting show.

As in prior years, it presented a chance to renew friendships, and to

meet people who had previously been just voices on the telephone.

Justina's Gems had a booth (in the Arena of the Community Centre -

where we are, too), and Justina faceted on her Ultra Tec while her husband

Robbie handled stone sales. They'll be back next year, so that's a chance

to see a super professional cutter in action....Here are a few of the people

at the show:

|

|

If you can attend any of the upcoming faceting shows you will find them fun

and instructive. Coming: Sept. 25/26 The So. Cal. Facetors Guild in Anaheim

CA, - Oct. 10/11 The Big Sky Facetors Guild, Great Falls MT, - Oct 30/Nov1

The Midwest Facetors Guild, Dearborn MI, - there's information attached about

these shows - as well as next year's San Jose show.

Attending the shows, if you can, is the important thing. As I've said in

previous letters, awards get a lot of attention, but most facetors find it

a 'spectator sport', and the show is the place to see them, see facetors in

action, see the displays, hear the lectures, meet people - have a good time.

Don't count out the idea of ever trying competition - you don't start out at

the Masters level - it teaches you a lot. You get a judge's score sheet, and

an idea of the ways in which you might improve - and you'll get congratulations

however low the score. Facetors are nice people - the only ones they ever poke

fun at are the people who score 'only' 99 and get beaten out by someone who

scores 99.25 - and then, gently.

WHAT'S NEW

We said in the last letter that something new is working its way through Design,

and it still is. I think it will be ready for the next Newsletter - hopefully not

too long.

Meanwhile, there are a few things to discuss. None of these design improvements

are urgent, but they are worth knowing about. A few of you will probably say

'Ah! Just what I need.' For most of you, however they are the sort of thing you

might want to think about if you send in your machine for recalibration They are

listed on the price list in a last section called 'Modifications'.

|

|

|

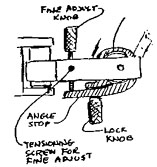

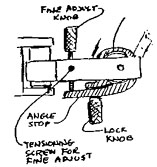

- We have improved the tensioning of the fine adjustment screw, to assure a

firm stop. The prior design had a feature for that purpose, a spring hidden

behind the screw. That design did not provide a way to increase the tension, if

desired. What we have done is to add a nylon-tipped set screw, accessible from

the side of the yoke, which allows easy control of tension - eliminating any

looseness. If your fine adjustment screw feels too loose - it should be nice

and firm - this is a good feature to add.

|

|

- The Riser Block (which rides -on the Lead screw) has had two setscrew

adjustments on one side. We have added two more, on the reverse side. These

are positioned to improve stability and we have found that a finer degree of

accuracy of calibration is maintained with this feature.

- We have changed to new Lead screw ball bearings. These are capable of a

heavy preload - which translates to elimination of backlash in reversing motion

- while providing smooth and easy operation of the Vertical Knob. If your

machine feels excessively stiff in its up and down motion - or if you detect

some degree of vertical backlash - you should consider this.

|

|

|

- The alignment feature of the Dop Chuck has been changed. The spindle

modification of about 5 years ago provides improved chuck accuracy, and it

continues to. The alignment feature (the internal pin in the spindle aligning

with the groove in the chuck), however, for several reasons, has been rethought,

and we have now returned to a pin in the chuck which engages an external groove

on the spindle - out where you can see it, and of proven sturdiness and accuracy.

(The internal pin has been fine for most, but there were enough comments received

for us to re-evaluate the feature) It is practical to modify existing product -

and we will modify as many chucks as you may have for the same price as modifying

one. So, if you are one who removes and reinserts chucks, you may want this

modification.

|

|

- Also on the subject of the Dop Chuck - we have improved

the gripping power of the brass collar, dividing it into four flexing

segments. This is useful if you are working on large stones. lf you

send your Head in for recalibration, we'll swap you a new collar for a

n old one - as many as you may have. If you just want new collars, they

are on the price list (and if you afterwards sent us back the old ones,

that would be nice).

There is another change, one that does not require any modification of

existing equipment. It's a new technique for alignment of the Index Gear,

and involves a change in the gear hub. The hub has been larger to accommodate

a brass-tipped set screw which will grip firmly anywhere on the Spindle, not

needing the flat (and, on new Spindles the flat has been eliminated). Instead

of repeatedly aligning the Tabling Block to the Index Gear, the Tabling Block

is set once. Subsequent changes in the Index Gear are made by setting the

Tabling block in place, holding it down against a flat lap, and setting the

Index Gear to it. That's all a lot easier, and a gear can be removed in this

method and later reset to the same place. An existing flat on the Spindle is

no problem - the Spindle can be rotated so the set screw bottoms elsewhere.

And speaking of Index Gears, we will accept orders for 32 teeth Index Gears.

We get many requests for these - people who became accustomed to other

machines that do offer a 32 seem to like them, and there are published

designs. (We should have them for immediate delivery, but we have a mystery

of missing inventory. Could anyone love 32's so much that he wanted a box full?

I'm about ready to remake them - at which time the missing ones will appear - but

not before. There is some Universal law involved).

Now, that does seem like an awfully long list. I suffer from uneasiness when I

ask myself why we didn't do some of these things sooner - there's the old

saying: so soon old and so late smart. Actually, these modifications all

happened as the result of a specific effort to pay attention to the sorts of

things we would see on machines that had come in for calibration, and to fine

tune the design as much as possible. I always think we are finally at the end

of the line - but there's always something.

FACETING TIPS.

With the growth of the Guilds and the specialized faceting publications that

are available, my 'tips' folder is getting pretty skinny these days. That's

fine - if you are availing yourself of one or more of those. There are a few

worthy things kicking around in that folder, however, so here goes:

- Bob Steel of White Oak Lapidary wrote to us with his recommendations for a

basic set of laps. He feels, and I must admit with some justification, that

Ultra Tec's recommendation for starting out is too sparse. Bob recommends: a

260, 600, 1200, lucite, phenolic, steel(!), along with a supply of 3000 and

100,000 diamond compound.

I think his letter deserves quoting (with a little editing for space). Bob

says: 'I recommend that the 260 be reserved for preforming and...main facets

on very large stones. A new 260 is very aggressive...it leaves very deep

scratches. This requires a cutting allowance for pre-polishing with the 1200

which is difficult for the beginner to estimate.....

'I recommend the 600 for cutting large facets. It has a rapid cutting action

but leaves a much smoother surface for pre-polishing. The beginner can cut

close to the final facet size.

'I suggest the 1200 be used for all small facets.... a 1200 cuts quickly and

leaves a surface which can be taken to polish, but with difficulty. This is

where the phenolic comes in.

'I recommend using the phenolic lap with 3000 diamond compound...after the

1200. The result is a very high pre-polish, easily seen...and easily brought

to a final polish. It is a versatile lap and produces a flat facet. It has

particular value in polishing corundum. This saves wear and tear on a 3000

diamond lap. ....this has some cutting action so care must be exercised.

'The plain Steel lap can be used to polish stones harder than quartz. I have

used Steel with 100,000 diamond compound to polish garnet, peridot, topaz,

CZ, beryl, and corundum....It produces a very flat facet and an excellent

polish. It should be used at a very slow speed....I apply a very little amount

of diamond, spread it with my finger using a little olive oil and then wipe it

with tissue while running at low speed...I now use spray diamond sparingly, but

still have to wipe it a bit. Too much diamond causes scratches and so will

excessive speed....

'I recommend using the lucite lap with cerium oxide for quartz. The other side

of the lap can be used with tin oxide for glass.

'All beginners should be cautioned to care for their expensive diamond laps.

A good scrubbing with detergent and a stiff brush promptly after use should

be a rule...'

Well, I took some editing liberties with Bob's letter, but I think I retained

the main thrust of it. Of particular interest is the recommendation to use the

Steel lap (he's not named Bob Steel for nothing!), and I still need to try it

myself. Also, I've been recommending a 3000 diamond lap with which I've had

very good results, but Bob seems to prefer the diamond compound on phenolic -

he expresses some concern about the life of the metal bonded 3000 diamond - I

haven't experienced that problem. He's also not in love with ceramic laps, but

there are many enthusiastic users of ceramic, including most of the competition

cutters.

You will get varying advice in regard to laps. That advice, however, is not so

much conflicting as it is just other. And they are all 'right' in the sense that

they are passing along what has worked for them. There seems to be enough subtle

differences in the way individuals polish so that what works for one person may

not work for the other. But, you do need to consider the advice that you get, and

keep trying until you have the 'right' way.

I get to speak to many facetors, and since I get many questions on polishing, I

jot down whatever recommendations I get on polishing laps - so I can pass it

along. Well, one question that keeps coming up is how to polish CZ. My jotted

down list of recommended laps includes: ceramic, tin, tin-lead, Last Lap, Fast

Lap, zinc, and now steel. How's that for a good firm recommendation? - and I'll

now get letters letting me in on the real right lap. And you know, every one of

those worked for somebody.

Well, as faceting tips go, that was a tip and a half, and I'11 save several

others for the next letter.

Miscellaneous happenings....Those of you who may have called Ultra Tec realize

that there is a new voice on the phone.

|

|

|

Dee Morrison has retired, after 8 years with Ultra Tec. Her husband retired

just a few months earlier and they are doing a lot of travelling. They've been

to Egypt and back, and now they are in China. The 'new [voice' belongs to

Delores Sanchez.

Delores worked with Dee for about a month, so she's had sort of a head start.

If you have occasion to call, I'm sure you will find that she is very helpful .

|

|

We were saddened to learn of the death of Dave Miller in an auto accident some

months ago. Dave, a resident of Flint, Michigan, was a super facetor, and was known as

the 'Grandfather of the Midwest Guild'. He'll be missed by his many friends....to end

on a more upbeat note, I'm looking forward to seeing many of you at the Southern

Califiornia Facetors Fair in September - Stay well.

From your friends at Ultra Tec, and in particular, me.

|

| : |

|

Double Diamond Dodecagon

Lee S. Fent, of Newton, Kansas is and MD who really enjoys his

faceting. He is one of the many doctors who facet, finding the activity

both relaxing and re-invigorationg after a stressful day. And, he takes

the time to design a stone now and again

Lee sent us this photo of himself at his UltraTec workstation. I suspect

it's always nice and neat like that (it would take me three days of

cleanup).

|

|

|

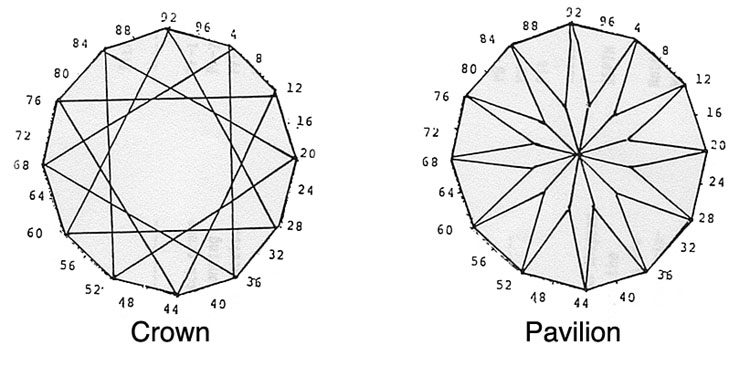

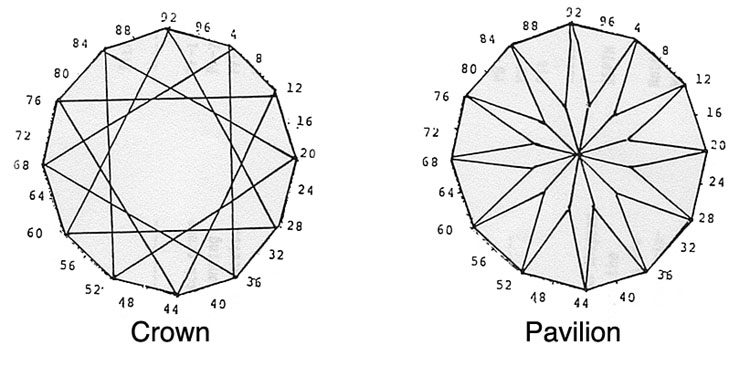

He writes about the Double Diamond Dodecagon: The design was initially

developed in an attempt to disguise inclusions in some topaz that I

picked up in Brazil. As the design progressed, however, I found that

the edge brilliance was much greater than in the standard brilliants.

I have cut this form in many materials, varying only the poavilion facets

to accomodate other gem materials, this seems to be the best for stones

from 8mm to 12mm. I have cut some smaller ones, but they are a little

'busy'. Incidentally, the cut is an easy one.

For those of you who would like to try a harder version, Dr. Fent's Texas

friend, Dr. Henry Owens, recommends using the pavilion form his

own O'Henry Cut (the Double O'Diamond Dodecagon?)>

Double Diamond Dodecagon

96 Index

Quartz Angles - main angle 42 deg.

Index Position as in the diagram

Pavilion Cutting Instructions

Step Angle

PF1 Girdle angle 90

PF2 Break angle 44

PF3 Main angle 42

Crown Cutting Instructions

Step Angle

CF1 Girdle angle 45

CF2 Main #1 angle 35

CF3 Main #2 angle 24

CF4 Star angle 18

|