|

The Ultra Tec Owners' Newsletter |

|

|

|

|

||

|

|

A VISIT TO ULTRA TEC. In February, we had interesting visitors, Ross Whipple and his wife Tarja, on a winter vacation to sunny California, from their home in Finland. They actually live near the Arctic Circle - where the year has one long day and one long night. They met and married in California, and moved to her homeland - away from the hustle and bustle. Ross is an enthusiastic facetor (his father, before him, was a gem designer). He's now Ultra Tec's representative in Finland - and hopefully he can lead the locals into a worthwhile way of whiling away the long Arctic night. |

|

|

ON THE ROAD AGAIN.

|

||

|

|

In particular, I was pleased to meet face-to-face with one of my

"voices on-the-phone"--our dealer in Portland, Grover Sparkman.

Did I say face-to Well Grover towered over me, but he looked down, and

I looked up. Grover is a self-effacing guy, who won't toot his own horn

- but let me tell you he does a superlative job in editing the Columbia

Williamette Guild's newsletter "Facets". Its probably the most consistently

informative of the Guild newsletters (well worth your getting a

subscription - see the Guild info. attached to this newsletter).

|

|

It was also nice to talk to old Ultra Tec friend Chris Herold who is now President of the Columbia Willamette Faceter's Guild. We knew Chris when he lived in nearby San Diego. At the conference, Chris was selling copies of the year's 12 best new faceting designs - and outstanding designs they are. They are very modestly priced and well worth getting (again - see the page attached to this newsletter). |

|

|

THINGS I LEARNED--and THINGS I RELEARNED...

|

||

|

This gives you an idea of it (if you haven't seen them yet). A main

question, of course, is whether the computer shows the "real world".

So, in a cooperative effort (prior to the Seminar), a group of stones

were faceted--all the same except for the varied angles--to see if the

computer results would be confirmed. And, not to keep you in suspense, the real world stones were as the computer predicted.

|

|

|

Looking at stones in the dark? The stones were laid out in a segmented

tray--corresponding to the computer print out. It wasn't easy, except in the

extreme cases, to see the differences - moving the position of the lamp

helped some, but it was still difficult. Bob Long watched our fiddling with

the lamp, and said "you need to look at them in the dark!" He not only had

us take the tray away from under the lamp, but had us set the tray around

in back of the showcase, in its shadow, in a very subdued light condition.

I'm not going to ask you to "guess what?", since I've telegraphed the answer,

but that's right, the variations in brightness, and the exact pattern of

brightness, were very apparent--in the dark. Try it (I just did, again - looking

at a group of stones, in a dresser drawer, in a dimly lit room--and again

confirmed what Bob had taught us).

|

||

|

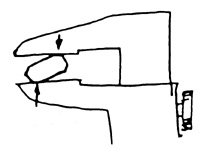

The positioning of corner girdle facets in Cut-Corner Rectangle Designs - "emerald cuts" - and their variants was also discussed at the Northwest Seminar. The discussion centred on the need to measure the position of those facets, for the same reasons that the length and width of the stone are measured. Norm Steele said that future design diagrams would provide those dimensions (in the form of a ratio to the stone's width). He acknowledged that performing a measurement of corner positions is a problem, since, on |

|

|

|

rectangular shapes (except for square

shapes), the corners are parallel but not in a straight line--and so using

a caliper to measure corner-to-corner accurately is most difficult - and,

with a long stone, it becomes impossible.

Well, that's not a problem for you. With your Ultra Tec's calibrated mast you can control that dimension in the first place--which leads me right into the following: ABOUT YOUR ULTRA TEC...Using the CALIBRATED MAST. A main advantage of the calibrated mast is that it allows you to control (when you wish) the size of the stone you are cutting. Since the calibrated mast allows you to know the distance from the surface of the lap to the stone, you can cut a precisely calibrated stone (without sneaking up on it, and "measuring it in"). Think about it--if you know the height reading that represents the surface of your lap, it's a matter of setting the height position of your dop above that lap surface by 1/2 the diameter of the stone you want to obtain. So, initially, you need to know the height reading of the lap surface (unfortunately different for each lap since the thickness varies, but fortunately, easy to determine). Here's a routine to do it: |

||

|

1. Dop a piece of material (you can do this with a stone on which you

are working, or you can do it as a special little project - using, say,

a piece of glass). Insert the dop into the Spindle and lock it in.

2. Set the Angle Dial at 90°. At O and 48 (on a 96 Index Gear--or, at 180° on whatever Index Gear you're using), grind two opposite flat surfaces. Grind to the stop, using the same height setting on both sides. Write down that height setting. 3. With a Millimeter Caliper measure the stone over the flats that you just cut. Write down that measurement--divide it in half - add that half-reading to the height setting (of step 2) - that's the height position of the lap. |

|

|

|

Having determined the height reading of the lap surface, you can cut an

exact sized stone by setting the height position of your dop above that

lap surface by 1/2 the diameter of the stone you want to obtain. For example:

Example 1: Say that using the above three steps, you determined that the surface of your lap corresponds to 14.64 cm. You want to cut a round girdle 12 mm (1.2 cm) in diameter. You would set the position of the dop 6 mm (.6 cm), (that's half of the 12 mm diameter that you want), above the lap surface--setting the Mast position to 14.04 cm. (the arithmetic: 14.64 cm - .6 cm = 14.04) Example-2: If you want a rectangular cut, 25 mm (2.5 cm) X 14 mm (1.4 cm). For the length, set the dopped stone 12.5 mm (1.25 cm - half the 2.5 cm) above the lap surface, that is, at 13.39 cm. For the width, set the stone 7mm (.7 cm--half the 1.4 cm) above the lap surface, that is, at 13.94 cm. Now, if the design is a cut-corner type (as almost all are), and if the diagram includes information about the measurement over the corners (as we've been promised future designs will), you can calculate the height position for those corners: The corner-to-corner measurement information is given as a ratio, for example, D/W=1.643 (that is, D [the corner to corner measurement] divided by W [the width measurement] equals 1.643 - or, one step simpler, D = W X 1.643). So, going back to our example, where we had a width of 14 mm, D = 14mm X 1.643, D = 23mm. Dividing that 23 mm in half, we get 11.5 mm (or, 1.15 cm), and so the height setting for the corner cut is 13.5 cm (the arithmetic: 14.65 cm [the lap surface height] minus 1.15 cm [the corner measurement we figured out). You mathematical swiftys have already figured out that since we are looking for 1/2D for setting purposes, we could have used the .7 cm half-width measurement that we figured out previously, giving: 1/2D = .7 X 1.643, 1/2D = 1.15 cm. OK? |

||

|

OK! Why this translating of mm's to "cm's" when stones are always

described in "mm's"?

Because the Scale is calibrated in cm's.

|

||

| : |

|

|

|

Here is a list of Guilds. Join one, if you are near enough--and in any event, subscribe to a newsletter (they are very informative--and there's always a design or two, or three). Columbia-Willamette Faceter's Guild Faceters' Guild of Southern California Faceters' Guild of Northern California Midwest Faceters Guild North York Faceters Guild Intermountain Faceters Guild Australian Faceters Guild New Mexico Faceters Guild WERE YOU MISSED ON THIS LISTING?--PLEASE CONTACT US, AND WE'LL ADD YOUR GROUP TO THE LIST. Contact the Columbia-Willamette Guild and ask about their design publications. They are very inexpensive (for example, $3 for the year's "12 Best")--they are available not just for this year, but for a number of preceding years as well. They're very nicely done - they are a "Best Buy". This was selected as "Best of the Best" at the Northwest Faceters Conference. It's by Sid Word, who is popular (for himself and for his designing) and prolific (you can get a collection of 42! of Sid Words designs from the Guild). |

||

|

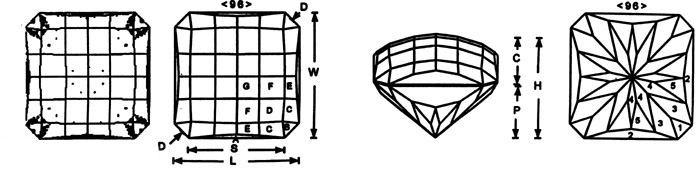

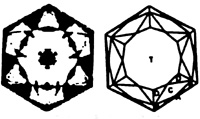

THE SOME TIMES DESIGNS This design was printed previously, for the conference of course, and in the July issue of "Facets", the newsletter of the Columbia-Willamette Guild. We usually try to have a design that hasn't been in print (at least not so recently), but this design was perfect to illustrate some of the things talked about in this newsletter--the brightness diagram on the upper left, and the callout for the corner dimension "D", given as a ratio to the width--as D/W=1.249. The cut is square, so this is a case where you can easily confirm the D dimension with a millimeter caliper.

Avg Brt 84 Spot+Amb, Trans 0.6 RI 2.17 07.073 Checkerboard Barion Pavilion Reference: WORD, Sid: FACETS, Mar 90, p3 96 Index L/W=1.000 P/W=0.569 C/W=0.251 T/WV=0 76+8 facets H/W=0.840 S/W=0.736 D/W=1.249 Rl=1.77 PREFORM CUTTING INSTRUCTIONS Step Angle Index Remarks PF1 41.5 96-24-48-72 Cut to TCP PF2 35.3 12-36-60-84 Cut to TCP. Meet PF1 G1 90.0 96-24-48-72 Fix stone size G2 90.0 12-36-60-84 Level false girdle Alternate preform is to cut G1 to give size, then cut G2 to give D/WV=1.249. D Is diagonal, W is the width. PAVILION CUTTING INSTRUCTIONS Step Angle Index Remarks G1 90.0 96-24-48-72 Girdle facet from preform G2 90.0 12-36-60-84 Girdle facet from preform P1 45.0 12-36-60-84 Locate girdle P2 68.0 96-24-48-72 Level girdle P3 43.0 09-15-33-39-57-63-81-87 Meet P1-P2-G1-G2 P4 41.5 06-18-30-42-54-66-78-90 Just reach line P2-P3 96-24-48-72 Cut to PCP P5 43.0 03-21-27-45-51-69-75-93 Meet P2-P3-P4 CROWN CUTTING INSTRUCTIONS Step Angle Index Remarks A 75.0 96-24-48-72 Fix girdle width B 41.0 12-36-60-84 Level girdle C 36.0 07-17-31-41-55-65-79-89 Meet A-B-G1-G2 D 23.0 12-36-60-84 Meet C-B-C E 34.0 03-21-27-45-51-69-75-93 Meet A-C (make equal) F 18.0 06-18-30-42-54-66-78-90 Meet E-C-D G 10.0 12-36-60-84 Meet F-D-F |

||